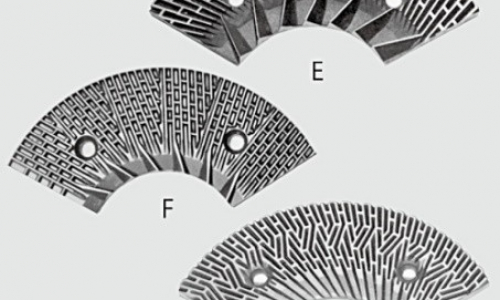

The pattern and material of the plate has a close relationship with not only pulp quality but also available feed amount of chip and specific power consumption. The pattern and material are selected based on experience and operation record. The plate is composed of two sections: breaking zone where chips are roughly broken, and refining zone for complete defibration and beating. The plate is made of high-chrome stainless steel. One set includes six plates. Three plates on each side (rotational and fixed sides) forms one segment. The photo shows the shapes.

Translation provided by Google

Refining Plates for KRK 2500 Series Refiners - OpTest

Home/Pulp and Fibrous Materials/Refining Plates for KRK 2500 Series Refiners

Refining Plates for KRK 2500 Series Refiners

| Product Name | Refining Plates for KRK 2500 Series Refiners |

| Product Code | KRK-2501 |

| Manufacturer | Kumagai Riki Kogyo Co., Ltd. ( KRK ) |

| Availability from OpTest | Exclusive to Canada, USA, and Mexico |

Plate diameter: 305mm in diameter

Material: stainless steel antiwearing material

Outer dimensions: 260 x 115 x 15mm

Plate weight: 1.5kg x 6 plates

See brochure for shape and features

These Refiner Plates can be used with the following Refiners:

KRK-2500-I KRK High-consistency Disc Refiner

KRK-2500-II KRK Continuous High-consistency Refiner

KRK-2503 KRK Pressurized Refiner