The FQA-360 features a flow cell that stays clean and does not plug. It easily measures difficult pulps without special pre-treatment or screening.

These pulps include:

• High Shive Content Pulps

• Mechanical Pulps

• Linerboard Pulps

• Diaper Fluff and Pulps with High Flocculation Propensity

• Recycled Fibers

• Non-wood (plant) Fibers and Long Synthetic (birefringent) Fibers

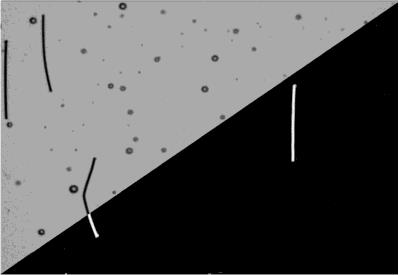

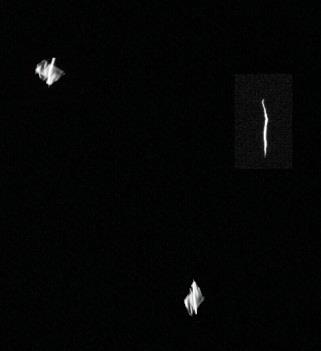

The 3mm rayon fibers above have no fines. However, air bubbles in the non-polarized part appear as fines

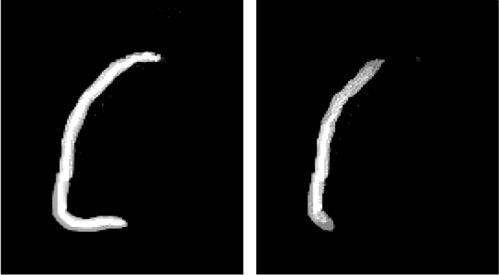

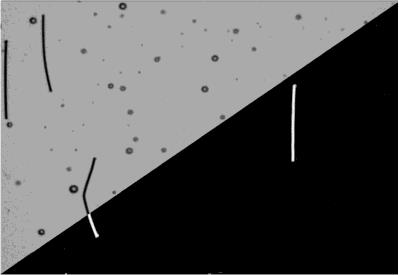

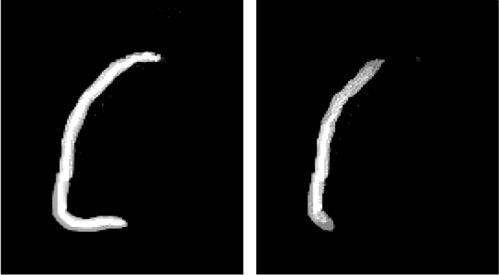

The same cellulose fiber viewed with circular polarized light (left) and linear polarized light (right). The ends of the curled fiber disappear in linear polarized light.

• Rapid & accurate measurement of length, width, curl & kink on fibers from 0.05 mm to 15 mm

• All fiber values are measured simultaneously with a single camera

• Combined fiber length and width data provides a useful tool for pulp blending

• Circular polarized light provides the most accurate measurement of fiber length and shape

• Sample cleaning and de-airing are unnecessary, unlike many non-polarized light methods

• More precise than non-polarized light methods

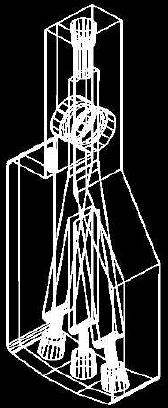

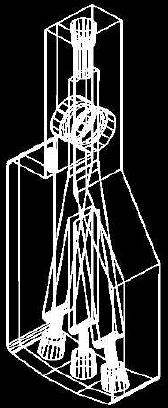

• The patented cytometric flow cell stays clean and prevents plugging

• Characterize pulps with contaminants such as ink, fillers, extractives and pitch

• Exceeds the Standard Specifications of Tappi T271, PAPTAC B.4, and ISO 16065-1

• Minimal maintenance

FQA-360 Software Options

COARSENESS, FIBER WALL THICKNESS AND HARDWOOD/SOFTWOOD RATIO MIXTURE SOFTWARE

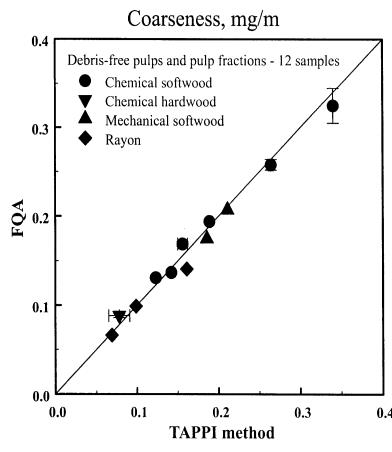

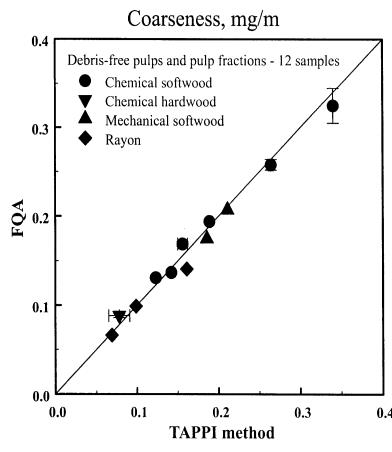

Coarseness: This option allows the FQA-360, and HiRes FQA, to accurately measure the mean fiber coarseness of a pulp sample.

The mean fiber coarseness is defined as:

coarseness = (OD sample mass) / (total fiber length)

Published results [Olson et al, Tappi J. (Oct. 1999)] found that the FQA agreed significantly with standard microscopy.

Coarseness accuracy with the FQA is ensured because the entire sample is drawn from the beaker eliminating errors from poor mixing or fiber flow fractionation.

The FQA-360 Coarseness measurement meets all the requirements and specifications of ISO Standard 23713.

Hwd/Swd Ratio: The software prompts the user to enter the average fiber length, Lw, and coarseness, C, of the parent species. It uses these values to estimate the fraction, F, of the softwood, sw, and hardwood, hw: in a pulp blend using the equations:

Fsw = Csw(Lwm - Lwh) / [ Csw(Lwm - Lwh) + Chw(Lws - Lwm)]

Fhw=1-Fsw

Fiber Wall Thickness: The average Fiber Wall Thickness (FWT) is calculated using the values of fiber width and the measured specimen coarseness.

The FWT histograms and distributions, as a function of fiber length and width, may also be available.

SHIVE ANALYSIS SOFTWARE

The combined cross-sectional area of the 3 fluid layers in the FQA cytometric flow cell is 33 mm². Consequently, large cellulose structures, such as shives, can be analyzed.

A published report (Joss et al, Appita J, 2006) found that 3 morphological parameters are required to properly describe a shive: Effective Length, Shive Area and Branch Index. The FQA-360 measures all 3 of these parameters.

Two shives may have the same effective length and area. By measuring the Branch index, it is possible to distinguish shives that are dense and compact from highly branched shives. Usually branched shives pose fewer problems for sheet runnability.

The optional Shive Analysis runs concurrent with the FQA-360 fiber measurements. The Shive Analysis results include the means, variances and distribution histograms for: Effective Length, Shive Area, and Branch Index.

VESSEL ELEMENT ANALYSIS SOFTWARE

The Vessel Element Analysis runs concurrent with routine FQA-360 testing. The results include the means, variances and distribution histograms for: The Effective Length, Effective Width, L/W aspect ratio and Area.

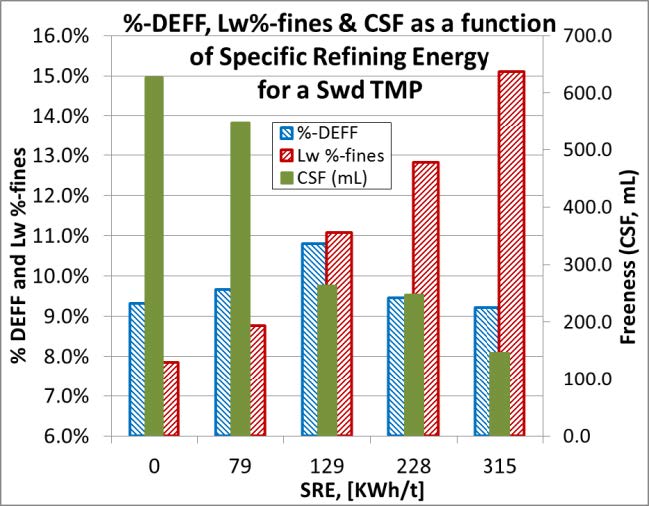

EXTERNAL FIBER FIBRILLATION SOFTWARE

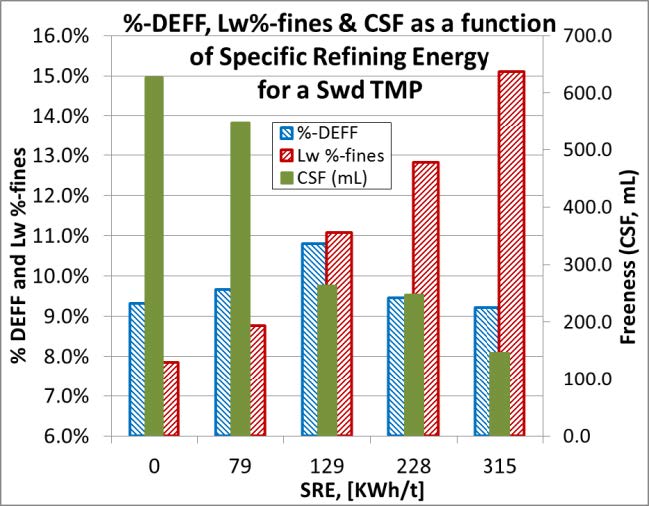

The FQA-360 measures the Degree of External Fiber Fibrillation (%-DEFF) with at least 2 times greater sensitivity than other optical techniques.

This is achieved with the use of circular polarized light which provides a fiber image contrast that is an order of magnitude greater than non-polarized light techniques.

The %-DEFF is the %-difference between the perimeter of the “smooth” fiber and the exterior perimeter of the fibrils. A higher value relates to a more fibrillated cellulose fiber.

FIBER ANALYSIS MEASUREMENTS

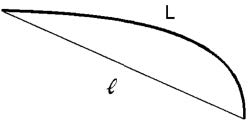

Fiber length is reported either as the fiber contour length, L, or the end-to-end (projected) length, ℓ. Fiber Curl is the gradual and continuous curvature of a fiber and is defined by:

Curl Index = (L/ℓ)-1

Kink is an abrupt change in the curvature of a fiber and is defined by the modified Kibblewhite's Kink Index. It is the weighted sum of the number Nx, of kinks within a range of "x" kink angles:

Kink Index = [2N(21-45)+3N(46-90)+4N(91-180)] / LTOTAL

The test results include means, variances and distribution histograms for:

• Fiber lengths (Ln, Lw, Lww) at ranges up to 15 mm and at a sensitivity of 0.001mm/test.

• Fiber widths and fiber width as a function of length graphs. Measurement sensitivity is < 1 µm/fiber and < 0.1 µm/test

• Curl Index (numeric & length weighted)

• Kink Angle, Kink Index and kinks/mm

• Numeric %-fines and length-weighted with user selected size limits and ranges

A dedicated built-in LCD screen displays results, status and starts test. Individual fiber images are sent to the PC Workstation for analysis and can be stored while performing all the test measurements.

OPTIONS AND ACCESSORIES

Options:

• Coarseness, Fiber Wall Thickness & Hwd/Swd Ratio Software

• Shive Analysis Software

• Vessel Element Analysis Software

• Degree of External Fiber Fibrillation (%) Software

• Calibration Check Fiber Kits

• Water Filter Replacement Kits

• Non-polarizing Optics: Used for opaque fibers and some fibers that do not depolarize light. Also, may be used for fiber length measurement according to ISO 16065-2.

Accessories:

• OpTiBlend: Stand-alone software that uses the data files from the HiRes FQA and FQA-360 to estimate the %-weight content of up to 5 species

• Beaker Carousel (BC) to automatically test up to 6 specimens

• PC Workstation & Excel™

Dimensions (including Beaker Carousel accessory)

• 610 mm L x 560 mm W x 760 mm H (24” L x 22” W x 30” H)

Weight (including Beaker Carousel accessory)

• 45 kg (98 lbs)

Connections

PC Workstation:

• Operating with Windows™ 10 Pro or later and containing:

• At least 16 GB DDR4 RAM, 2 ea. Gigabit Ethernet connections, a USB port, and Microsoft Excel™ (2016 or later)

• Minimum 20” display is recommended

• Power: 200W stable within 5% and transient free within 10%

• Water: Pressure = 275 kPa (40 PSI) mineral free (less than 50 mg/L residue after evaporation) filtered (external at 5 μm) air-free (less than 0.05% free and bound air by volume)

![]()