The Hi-Op PPF Formation Values are relative to “perfect paperboard” and to user selected “reference sheets”.

Samples are easily compared to selected reference sheets such as a competitor’s paperboard or the “best” sheet produced on a particular paperboard machine. The Relative Formation Values are reported for each size component. If this value is one, then the formation of the tested paperboard and reference paperboard are equal. If the value is greater than one, then the tested paperboard is better than the reference paperboard, and vice versa. Relative Formation measurements save time and money when determining the difference between sheets and when optimizing the paperboard machine forming sections.

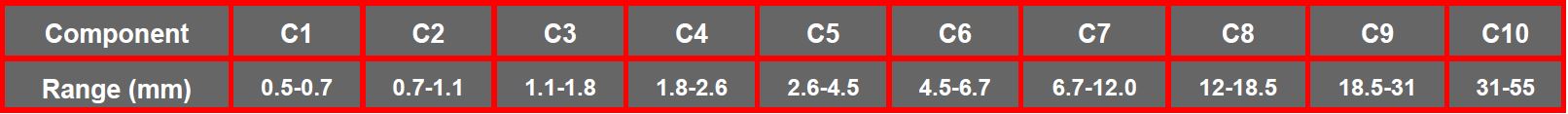

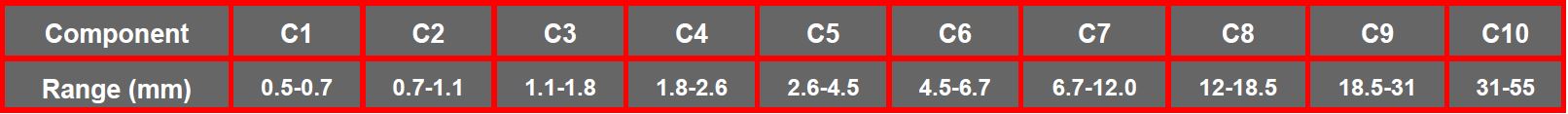

Formation quality values are reported for each of the 10 components (size ranges) of formation:

Process changes affect formation values, at different size ranges. Likewise, different size ranges relate to different sheet properties.

Typical relationships:

ACKNOWLEDGEMENT

The advanced algorithms were developed at McGill University by Dr. J-Ph Bernié and Prof. M. Douglas (US Patent 6,301,373).

FEATURES

• Precise optics & illumination

• Solid-state camera with 65 µm/pixel resolution

• Auto calibration

• Diffused proprietary solid-state (LED) lighting system with automatic intensity control

• Paperboard strip profiling capability

• Rapid measurements (typically < 1 s / field)

• Up to 3000 g/m² sheets, depending on recycled fiber and residual-ink content

OPTIONS

• Fully validated “turn-key” computer

• Pattern Recognition Software

DIMENSIONS

Light Control Unit

61cm (24") L x 63cm (25") W x 44cm (17.5") H

CONNECTIONS

• 120Vac/60Hz or 240Vac/50Hz, 1 phase, 600 W min. The power must be stable, within 2%, and transient free within ± 10%

• Computer with Microsoft Windows™ 11 Pro or Later, Microsoft Excel™ 2016 or Later and one USB port