The On-machine Dirt In-speck-tor (ODI) measures visible dirt in sheets according to ISO 5350-4 & TAPPI T563 standards.

The ODI measures the number, size and equivalent black area (EBA) of visible dirt specks far more precisely than the human eye. Operating on most pulp machines, it measures dirt specks on sheets moving at 1200 m/min to a resolution of 0.02 mm². The ODI provides the information you need to ensure a high and consistent quality product.

The ODI reports both the physical sizes, typically used for process optimization, and EBA sizes according to ISO/TAPPI standard methods for grade (customer) cleanliness specifications.

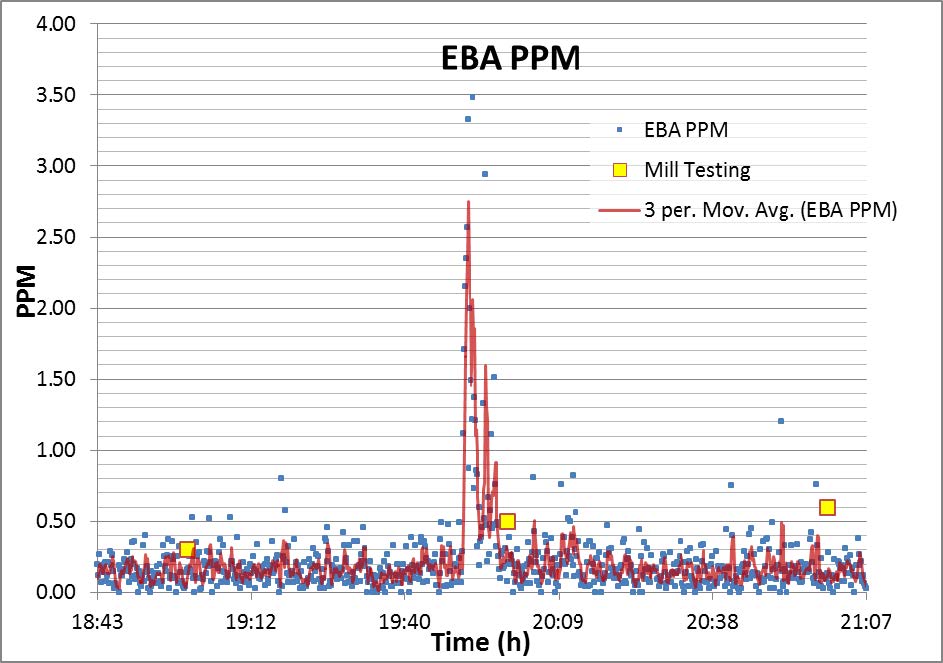

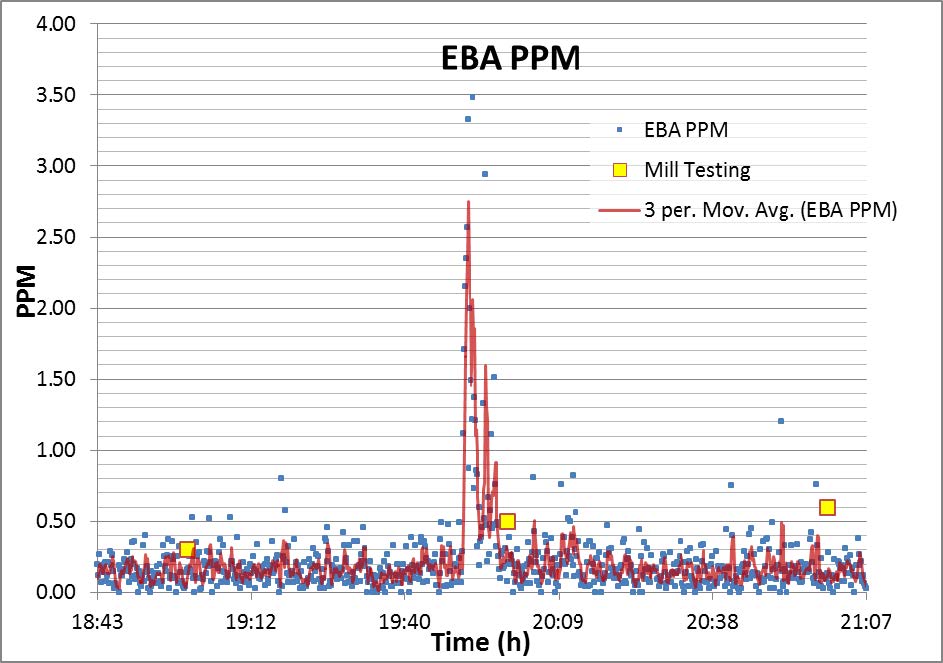

The reports include both the PPM (mm²/m²) and the number of specks/m². Both are required to make informed decisions on production quality acceptance.

ADVANTAGES

• Robust camera-based industrial sensor with a greater depth of field and more diffuse illumination as required by the standard methods

• All solid state light source meeting the spectral specifications of the standard methods

• Measures up to 250 m²/ hr, or more, of pulp, paper, and board with no off-line manipulation of sheets

• EBA calibration as per the standard methods

• Calibration plates traceable to ISO Level II facility

• Available in on-machine single point or traversing scanner versions

• Networking to mill wide and OpTest service and support centre

USER INTERFACE

• Several network communication options between the ODI and the user are available.

• The Physical and EBA speck count/m2 and PPM (mm2/m2) are available to mill wide IT systems.

• ODI Report Software can reside on a remote computer and can provide more detailed analysis reporting. All data can be viewed and manipulated by Microsoft Excel™.

(source: Tappi PEERS Conf.– Norfolk, VA – 2017)

CALIBRATION

Calibration checks are performed automatically several times a day.

OpTest provides an off sheet calibration apparatus with an ISO 2 level traceable calibration standard, and a spare, that meet the requirements of the standard methods. The off sheet calibration is performed monthly and takes less than 2 minutes.

RESULTS AND REPORTS

The ODI provides the most important dirt results. These include:

• Physical and EBA speck count / m² and PPM (mm² / m²) average results and distributions

• Percent counting uncertainty

• Shive counts (option)

• %-reflectance within 380-760 nm (option)

DIMENSIONS

ODI Sensor 28 cm L x 28 cm W x 20 cm H (11" L x 11" W x 8" H)

Computer Bay 80 cm L x 70 cm W x 45 cm H (32" L x 28" W x 18" H)

The above mentioned are installed on a fixed point (2 m) or traversing (<15 m) scanner.

CONNECTIONS

Power:

110-230V, 50/60 Hz at 1.5 kW. The power must be stable, within 5%, and transients below ± 10 %

Communications:

LAN and/or universal KepServer™ communication platform to PLC or DCS

Instrument Air Supply:

600 kPa (90 PSI) at 20C – 25 C, oil free,

Continuous demand of at least 0.25 m³/min (10 CFM)